Raising a timber framed gazebo on a floating dock in Alabama required math skills and equilibrium!

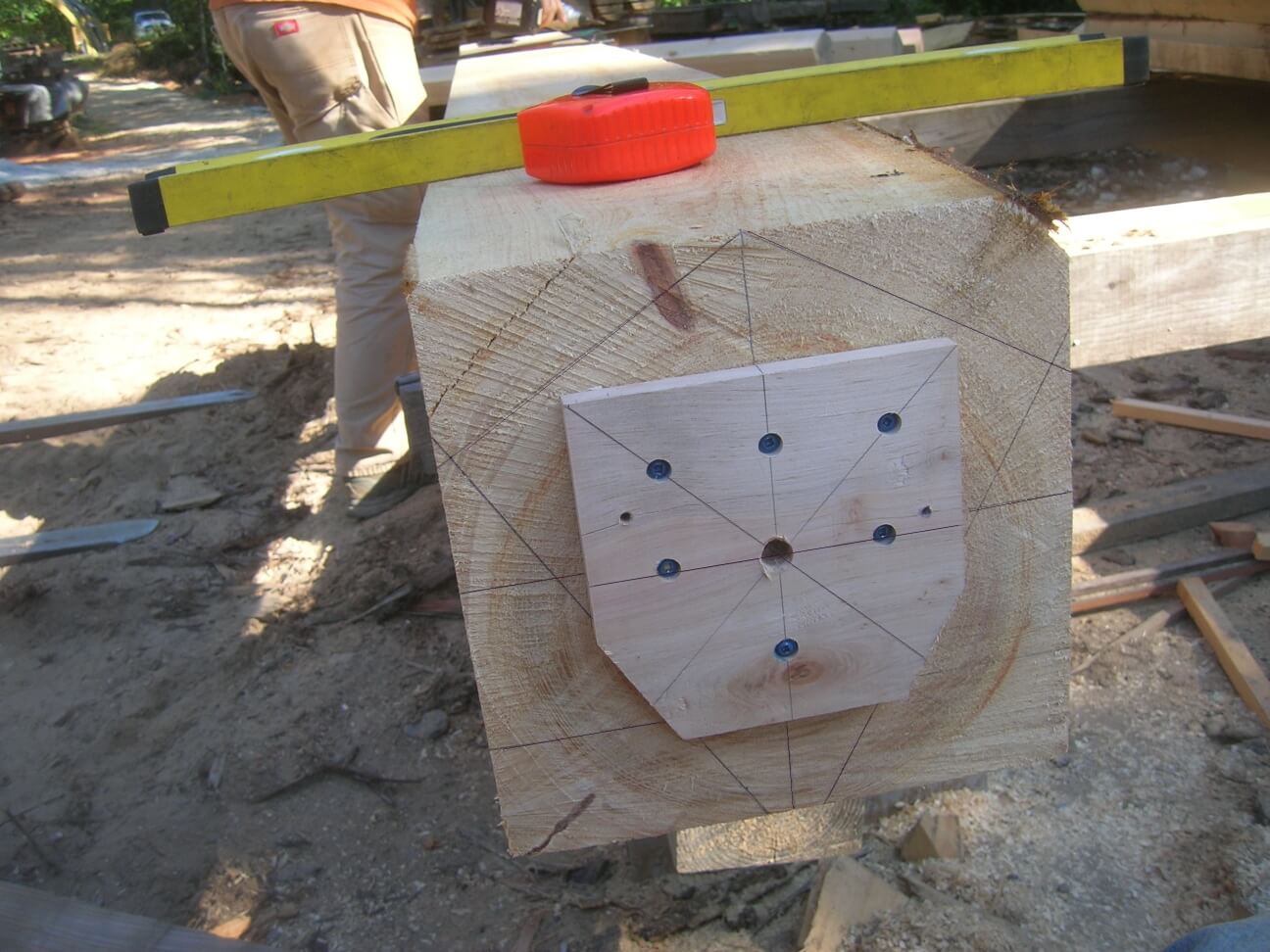

The Cypress octagonal gazebo required some different layout. We cut the five-sided posts on our sawmill, along with the six-sided "boss pin."

Boss pin is the name of the timber that drops down from the peak of the gazebo. The rafters and knee braces are all connected to this timber with mortise and tenon joinery and it holds the whole roof together. It's in charge, hence the name!

As wood ages it shrinks. If the boss pin had shrinkage the entire roof structure would be affected and could lower. To ensure this doesn't happen we sometimes hollow out the boss pin where the rafters connect to it and insert kiln dried oak. Kiln drying removes excess moisture and significantly decreases shrinkage.

Timber frame gazebo raising

Cutting a five-sided post on the sawmill

Testing the timbers for level!

On site at the lake in Alabama

Timber frame gazebo raising

Carlton, Jonathan & Jeremy assembling the timber frame

Ready for pegs and the T&G ceiling

After each cut the timber is rotated for the next step.

Starting to assemble and test fit in the shop

Instead of the usual crane, we used our client's track hoe.

Timber frame gazebo raising the roof truss structure

Looking up while on the floating dock could be disorienting!

Boss pin decorative detail

Black walnut pegs create contrast on boss pin knee braces

Finished gazebo being put to good use!